An Unbiased View of Laser Scanning Solutions, Llc.

Wiki Article

What Does Laser Scanning Solutions, Llc. Mean?

Table of ContentsUnknown Facts About Laser Scanning Solutions, Llc.Indicators on Laser Scanning Solutions, Llc. You Need To KnowNot known Details About Laser Scanning Solutions, Llc. About Laser Scanning Solutions, Llc.

In order to position a laser beam in two measurements, it is feasible either to revolve one mirror along 2 axes - utilized mainly for slow scanning systems - or to reflect the laser beam of light onto two closely spaced mirrors that are mounted on orthogonal axes (https://www.easel.ly/infographic/m5wmmu). Each of the two flat or polygon (polygonal) mirrors is then driven by a galvanometer or by an electrical motor respectively

Some applications call for positioning the emphasis of a laser beam of light in three measurements. This is accomplished by a servo-controlled lens system, usually called a 'emphasis shifter' or 'z-shifter'. Numerous laser scanners even more permit changing the laser strength. In laser projectors for laser television or laser display screens, the three fundamental colors - red, blue, and eco-friendly - are incorporated in a single light beam and afterwards mirrored with each other with 2 mirrors.

Modern lasers can reduce steel blocks with a density of 10 cm and even more or ablate a layer of the cornea that is just a few micrometers thick. The capacity of lasers to harden fluid polymers, along with laser scanners, is used in fast prototyping, the ability to thaw polymers and steels is, with laser scanners, to produce parts by laser sintering or laser melting.

The Best Strategy To Use For Laser Scanning Solutions, Llc.

That card transforms the obtained vector data to activity info which is sent to the scanhead. This scanhead contains two mirrors that are able to deflect the laser beam of light in one degree (X- and Y-coordinate). The 3rd measurement is - if required - recognized by a particular optic that is able to move the laser's focal point in the depth-direction (Z-axis).For these situations it is very important that the laser has as little a focal factor as feasible (laser 3d scanning). For enhanced laser scanning applications and/or high product throughput throughout manufacturing, scanning systems with greater than one scanhead are used. Right here the software needs to regulate what is done exactly within such a multihead application: it is possible that all available heads need to mark the same to finish handling quicker or that the heads note one solitary task in parallel where every scanhead executes a part of the task in instance of large working areas

In these gadgets, a semiconductor laser light beam is usually checked with the aid of a powerful mirror scanner. In order to identify its relative placement to the area station, laser scanners developed into the front of the area transporter scan the shape of the area station and then determine, through a computer system, the navigating commands.

The uses just listed which are only a tiny sampling of laser scanning applications have extensively differing technological requirements. This includes parameters like scanning rate, the size of the location or volume that should be covered, the laser power entailed, the cost, size, dependability, and life time of the scanner, and much a lot more.

An Unbiased View of Laser Scanning Solutions, Llc.

Depending upon the nature of the task, galvanometer scanners are frequently made use of in pairs. Specifically, in this case they are mounted with their scan directions at appropriate angles per various other. This allows the laser light beam to get to any kind of point in an aircraft. For many applications, specialized check optics, like an F-theta lens, are utilized to focus the beam of light on the final surface area.

Going back to 1960, when Theodore Maiman developed the initial laser, this kind of light has actually progressed into a device utilized across industries. From clinical therapy to manufacturing processing, the power of lasers is used across a myriad of sectors and for lots of sorts of applications. When most consider lasers, the common red light lasers frequently enter your mind.

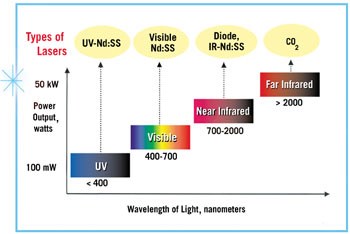

There are over 8 kinds of lasers across three classifications! Light wavelength distribution map Solid-state lasers are kinds of lasers that utilize a solid material as its gain medium.

Unknown Facts About Laser Scanning Solutions, Llc.

When a laser diode radiates light on the drugged material, the neodymium atoms are thrilled and send out light. This light is after that enhanced by the material and released as a laser light beam. YVO4 needs big quantities of energy to generate a secure high-output energy quantity. This medium has actually recently taken control of in popularity compared to YAG tools.

These laser types make use of gas as the medium instead of a solid or fluid. The 4 kinds of gas lasers are Carbon dioxide, He-Ne, excimer, and argon. CO2 gas lasers have the lengthiest wavelength compared to fiber, YAG, and YVO4.

Because he said of the lengthy wavelength, there is more heat transfer than various other lasers. CO2 lasers are commonly utilized for cutting products.

Report this wiki page